Benefits of Composite Decking Sheets

Composite construction has contributed to the role for steel frame construction in the construction industry. The industrial building sector in India. The composite construction’s prime benefits are:

Safety of Decking sheets

The decking is able to function as a safety canopy giving a safe platform for operation and shielding the workers below from being harmed by falling objects from above.

Decking Sheet Save in weight

The composite deck is more durable and stronger than other floor structures and can help reduce both the mass and weight of the main structure. Therefore, the size of the foundation can also be reduced.

Decking Sheet Save in transport

Decking sheets are light and are available in pre-cut lengths that are tightly packed into bundles. A typical truck can move more than a thousand square meters worth of decking. This means that fewer deliveries are required in comparison to other types of construction.

Decking sheet provide Sustainability

The steel can be reused without compromising its characteristics. This makes the frame made of composite steel the most stable option. “Sustainability” is an important basis for clients, and at least 94% of all steel products for construction can be recycled or re-applied when a building is demolished.

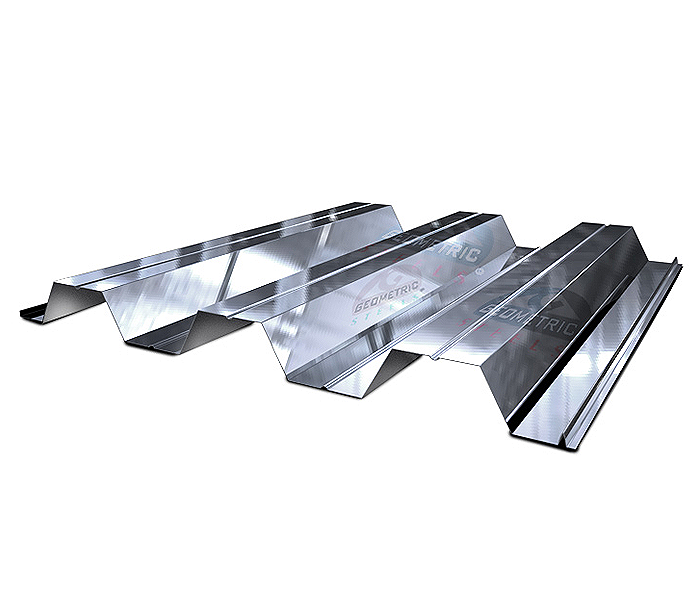

Decking sheets make it easy for installation

Pipes and cables are able to be suspended from hangers with specific "dovetail" recesses, which are then rolled into decking profiles for the installation of various services like electricity, telephone and network cables to I.T. The hangers are also able to facilitate the construction of false ceilings as well as ventilation equipment.

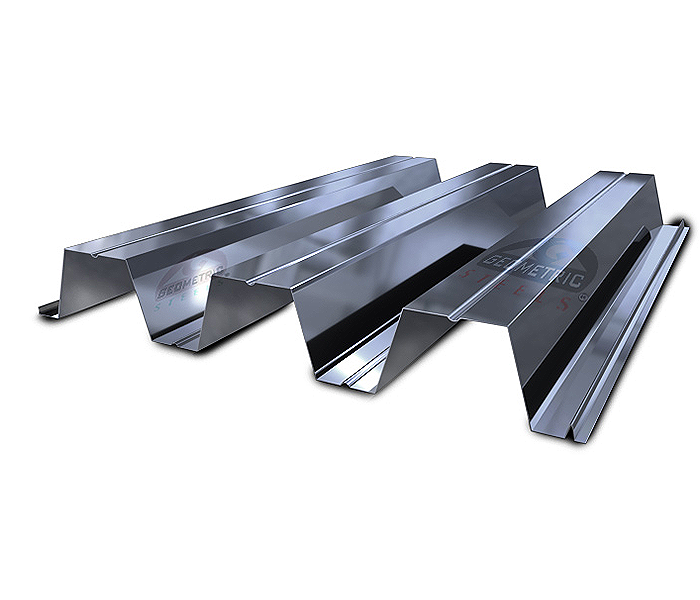

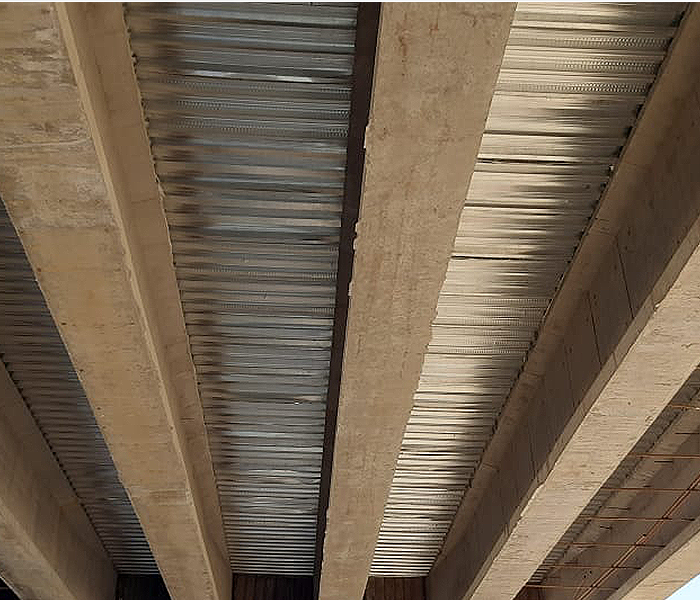

Decking has Shallower construction

The hardness and resistance to bending of the composite beams mean you can finish shallow floors better than non-composite construction. This can mean smaller floor heights, more space to accommodate low-floor services or multiple floors at the same overall height. This is especially true for slim-floor construction where the depth of the beam is carried within the depth of the slab.

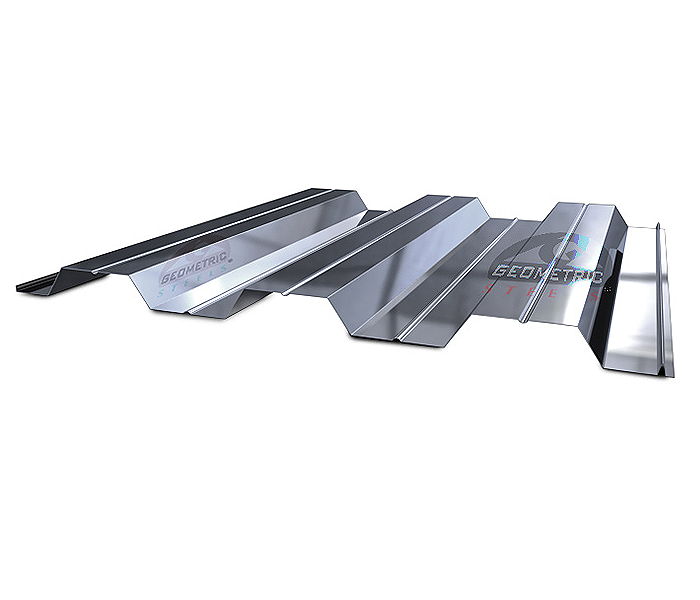

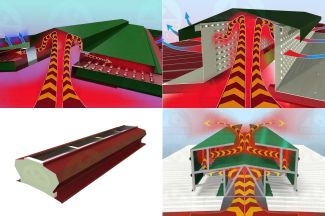

Decking Sheet provides Structural stability

In the event that decking fixings are designed and designed to support the weight, the decking will be efficient in lateral restraining the purlin. Furthermore, the decking could be constructed as a huge floor to help deflect wind's force during construction, and the composite slabs could be used as a diaphragm for the design. The floor's structure is strong due to the expansion of the various decking concrete supports, and the principal structure.

Decking Sheet provide Speed of construction

Multiple decking is able to be hung onto the structure by using cranes and each deck is anchored by hand. This reduces the time required for cranes and lets one crew layover 350m2 of decking every day, according to the size and shape of the structure. The decking used as a platform can be used quickly to build. It is possible to pour a huge part of the floor in a short time. Floors can be concreted in quick sequence. Fiber reinforced concrete will further limit the duration of the program since the time required to install reinforcement is greatly decreased.

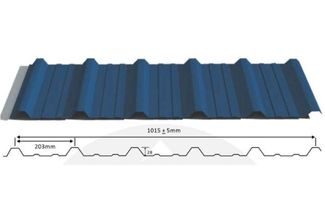

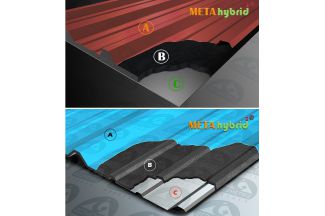

Decking Sheets and shear stud

The hot-rolled steel sections of the decking sheets are joined with the concrete slab. The shear studs are essential to transfer the force between the steel sheet with the slab. The sheer connectors offer longitudinal connections between the steel section and concrete, which then transform into studs which are placed on top of the steel piece. Connectors have to be able to stand up to the force of uplifting caused by the possibility that slabs will break off from the beam as it flexes. For Shear studs, this can be carried out from the top of the stud. Shear studs are typically connected to the beam through the sheet of deck. This enables the slabs of concrete to be formed into the top flange of the beam when the concrete sets and forms solid sections that are able to help support the slab load.