Understanding Deck Sheet Profile: Technical Insights and Their Role in Modern Construction

In the evolving landscape of construction, innovative materials and techniques are pivotal to improving efficiency, sustainability, and structural integrity. One such innovation is the use of deck sheet profiles, which have revolutionized the way modern buildings are constructed. Deck sheet profiles, particularly steel decking sheets, play a crucial role in composite floor systems, providing a blend of structural performance and cost-effectiveness. This blog delves into the technical aspects of deck sheet profiles and their utility in contemporary construction practices.

We are going to explore following topics for deck sheet profile

Technical Aspects of Deck Sheet Profiles

Advantages of Deck Sheet Profiles in Modern Construction

What are Deck Sheet Profiles?

Deck sheet profiles are corrugated metal sheets, typically made from galvanized steel, used in construction to support concrete slabs. These sheets serve as permanent formwork and tensile reinforcement, providing a stable platform for pouring concrete and contributing to the composite action between steel and concrete. The profiled decking sheet increases the load-carrying capacity and stiffness of the concrete slab, allowing for longer spans and reduced structural depths.

Types of Steel Decking Sheets

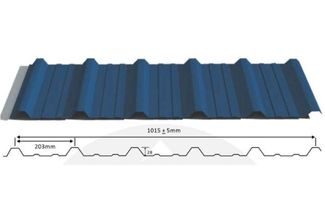

1. SteelDECK 52:

• Crest Height: 52 mm

• Features: Ideal for light to medium load applications, offering a balance between strength and weight.

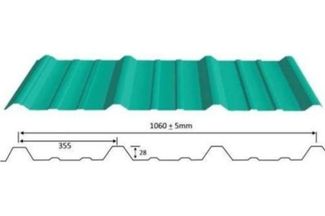

2. SteelDECK 76:

• Crest Height: 76 mm

• Features: Suitable for medium to heavy load applications, providing enhanced structural performance.

2. SteelDECK 102:

• Crest Height: 102 mm

• Features: Designed for heavy load applications, ensuring maximum load distribution and structural integrity.

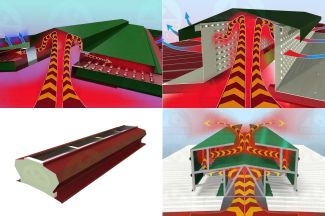

Technical Aspects of Deck Sheet Profiles

Shear Interaction

The strength of composite slabs with decking profiles is primarily governed by the shear interaction between the concrete and the steel deck. The corrugations in the decking sheet create mechanical interlocks with the concrete, enhancing the shear bond and ensuring composite action.

Finite Element Modeling (FEM)

Finite Element Modeling (FEM) is a powerful tool for analyzing the behavior of composite slabs with deck sheet profiles. Using software like ANSYS, engineers can simulate various loading conditions and design configurations to predict the performance of composite slabs. This includes assessing factors such as deflection, stress distribution, and failure modes.

Material Properties

Concrete Concrete used in composite slabs typically exhibits a multilinear isotropic behavior, characterized by different properties in its elastic and plastic zones. Key parameters include the modulus of elasticity, Poisson's ratio, and ultimate compressive strength.

Steel The steel used in decking sheets is often modeled as an elastic-perfectly plastic material. This means it behaves elastically up to its yield point and plastically beyond that, without further hardening. This property is crucial for accommodating the stresses and strains experienced during the service life of the structure.

Load-Deflection Behavior

Composite slabs with deck sheet profiles demonstrate distinct load-deflection behavior, which can be studied using load-deflection curves obtained from both experimental and numerical analyses. These curves provide insights into the stiffness, ductility, and ultimate load-carrying capacity of the slabs.

Crack Patterns

The crack patterns in composite slabs are indicative of their failure modes. In slabs with shear connectors or steel reinforcement, cracks typically initiate at the bottom of the slab and propagate upwards. The presence of shear connectors enhances the shear bond, reducing the likelihood of delamination and improving overall structural performance.

Advantages of Deck Sheet Profiles in Modern Construction

1. Structural Efficiency

Deck sheet profiles enable the construction of longer spans with fewer supports, reducing the overall structural depth and material usage. This results in lighter structures and more flexible design options.

2. Speed of Construction

Using deck sheet profiles accelerates the construction process. The sheets act as permanent formwork, eliminating the need for temporary supports and allowing for faster pouring of concrete.

3. Cost-Effectiveness

The composite action between the decking sheet and concrete reduces the amount of concrete required, lowering material costs. Additionally, the reduced construction time translates to lower labour costs.

4. Versatility

Deck sheet profiles are suitable for a wide range of applications, from residential buildings to industrial facilities. They can be customized to meet specific design requirements, including different profiles, thicknesses, and coatings.

5. Enhanced Load-Carrying Capacity

The corrugations in the decking sheets increase the load-carrying capacity of the composite slab, distributing loads more evenly and improving overall structural performance.

6. Improved Safety

The use of deck sheet profiles enhances the safety of construction sites by providing a stable platform for workers and reducing the risk of formwork collapse.

Case Studies and Applications

Analytical Study on Concrete Slabs with Decking Profiled Steel Sheets

A study conducted by Tarek Ali, Sameh Yehia, and Mohamed El-Didamouny presents a detailed analysis of concrete slabs with decking profiled steel sheets. Using finite element modeling, the study evaluates the performance of different slab configurations under various loading conditions. Key findings include:

• Load Carrying Capacity: The use of profiled deck sheets can reduce concrete volume by 20% without compromising structural integrity.

• Shear Connectors: The presence of shear connectors significantly enhances the load-carrying capacity and ductility of the slabs.

• Crack Patterns: Slabs with shear connectors and steel reinforcement exhibit ductile failure modes, with cracks initiating at the bottom of the slab and propagating upwards.

Practical Applications

1. Commercial Buildings: Deck sheet profiles are widely used in commercial buildings for floors and roofs, providing structural efficiency and design flexibility.

2. Industrial Facilities: In industrial settings, deck sheet profiles support heavy loads and long spans, making them ideal for warehouses and manufacturing plants.

3. Residential Construction: In residential buildings, deck sheet profiles offer cost-effective solutions for multi-story structures, ensuring safety and durability.

Conclusion:

Deck sheet profiles are a cornerstone of modern construction, offering numerous technical and economic benefits. Their ability to enhance structural efficiency, reduce construction time, and improve load-carrying capacity makes them indispensable in contemporary building practices. As construction technology continues to evolve, deck sheet profiles will remain a critical component in the quest for safer, more efficient, and sustainable structures.

References

1. Geometric Steels Steel Decking Sheets: https://steeldeckingsheets.com/

2. International Journal of Advanced Research in Engineering and Technology (IJARET), "Behavior and Resistance of Composite Slabs Experimental and Finite Element Analysis," Volume 11, Issue 12. Retrieved from https://iaeme.com/MasterAdmin/Journal_uploads/IJARET/VOLUME_11_ISSUE_12/IJARET_11_12_094.pdf

3. Veljkovic, Milan. "Behaviour and Resistance of Composite Slabs: Experimental and Finite Element Analysis." Lulea University of Technology, S-971 87 Sweden, 1996.

4. Shanmugam, N. E., Kumar, G., & Thevendran, V. "Finite Element Modelling of Double Skin Composite Slabs." Journal of Finite Elements in Analysis and Design, 579-599. DOI: 10.1016/S0168-874X(01)00093-2, 2002.

5. Baskar, R., & Antony Jeyasehar, C. "Experimental and Numerical Studies on Composite Deck Slabs." International Journal of Engineering Research and Development, ISSN: 2278-067X, ISSN: 2278-800X, Volume 3, Issue 12, September 2012.

6. Manjunath, T. N., & Sureshchandra, B. S. "A Study of Affordable Roofing Systems with Composite Slab." ISSN: 2321-8169, Volume: 5, Issue: 8, 200–205, 2018.

7. Abbas, H. S., Bakar, S. A., Ahmadi, M., & Haron, Z. "Experimental Studies on Corrugated Steel-Concrete Composite Slab." Journal of Civil Engineering, DOI: 10.14256/JCE.1112, 67 vol. 3, pp. 225-233, 2015.

8. Egyptian Code of Practice for Design and Construction of Concrete Structures ECCS (203-2007).

Our Other Products

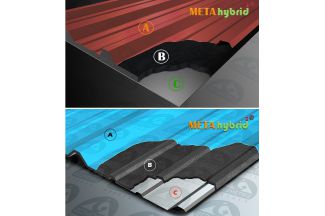

METAhybrid®

METAhybrid® Thermal Insulated metal sheets with 6mm to 50mm thick thermal and sound insulated roofing solution.

Read More

SteelzipTM

SteelzipTMStanding seam that covering entire building with panels joined together with a double lock standing seam.

Read More

Airflow Ridge Vent

Airflow Ridge vent is a unique ventilation product by Geometric Steels, installed at the peak and running the length of ridge line. Best for solar roof.

Read More

Smoke Vent

Prompt venting in case of fire is essential. Smoke vent is a device fitted on roof that will allow smoke to escape providing a safer means of escape.

Read More

Metal louvers

Geometric steels specialize in customized louver manufacturing aluminum and steel powder-coated louvers with all built-in facilities.

Read More

Polycarbonate Skylight Sheets

This is the simplest method of getting controlled light transmission through a steel sheet roof. Available in all required profiles.

Read More

Flashing and Accessories

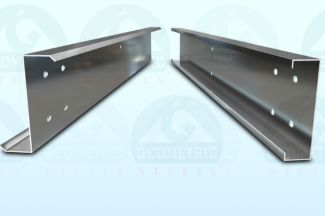

Geometric steels USP in design and manufacturing flashing up to 5000mm length in 0.4mm to 3.00mm thickness in all metal.

Read More

Roof Access Hatches

Low-profile design that allowed architects to keep clean building lines. Economical as compared to conventional staircase periphery construction.

Read More

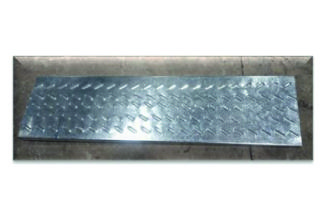

Roof Walk Way

Roof Walkways provide safe access to rooftop equipment and maintenance while eliminating damage to roof Sheets from foot roof traffic.

Read More